In this Topic Hide

How is Data Transferred Across the Bus

From ATS Bus to Shop Floor Equipment

From Shop Floor Equipment to ATS Bus

ATS Bus acts as a standardised channel through which all production data can be exchanged. Instead of having to create a customized connection for every combination of ATS software, enterprise software and plant machinery everything simply plugs into ATS Bus.

Order information such as:

o What order is being carried out?

o What needs to be done to complete this order?

Production details such as:

o What material has been produced?

o Which equipment was used?

Equipment status details such as:

o What’s the current status of the equipment?

o How long was the machine running for?

Although there are a lot of technical things happening within the system, the setup of ATS Bus and transfer of data can be simplified to the following:

1. Items are connected to the bus using a Bus Stop.

2. Each Bus Stop translates the data from outside world into the standard B2MML format (an ISA-95 standard for XML) before putting it on the Bus.

3. The information within the message is available to everyone on the Bus.

4. When another Bus Stop sees information in the message that it wants it translates it and sends it on to the relevant destination.

Everything that wants to connect to ATS Bus to send or receive data, such as an IT system (e.g. MES, ERP, PLM), equipment on the factory floor or other ATS software, must connect via Bus Stop.

There are different types of Bus Stop for different entities. For a description of all of the available Bus Stops you can see the Bus Stop Overview. but we'll look at a couple of examples here.

Let's say that you want to be able to send an order from an IT system down to the production line and once the order is complete you want the equipment on the production line to send a message up to the IT system to say that it's complete.

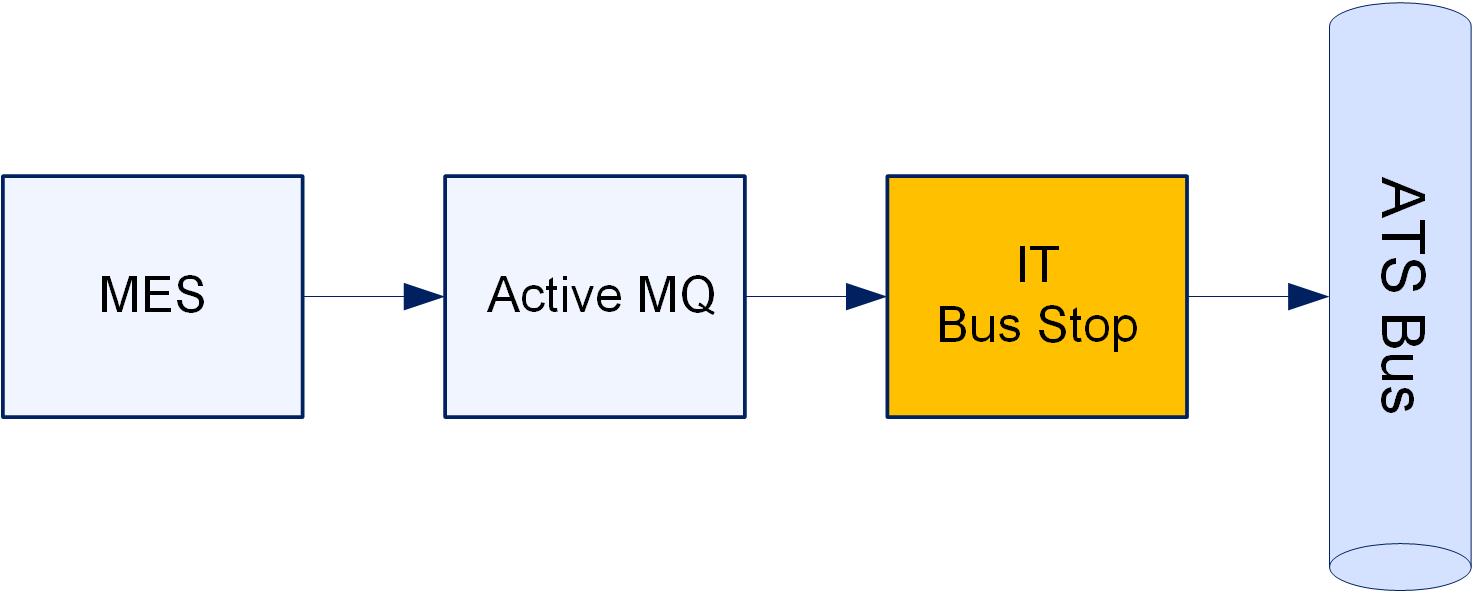

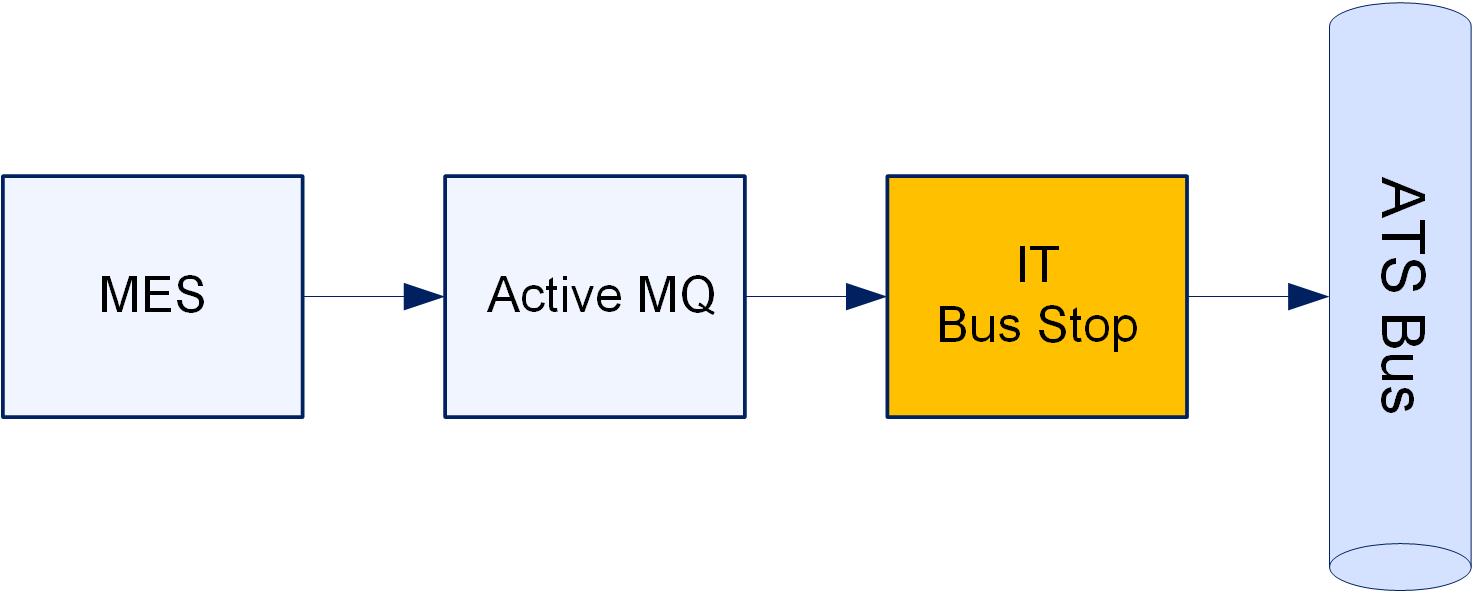

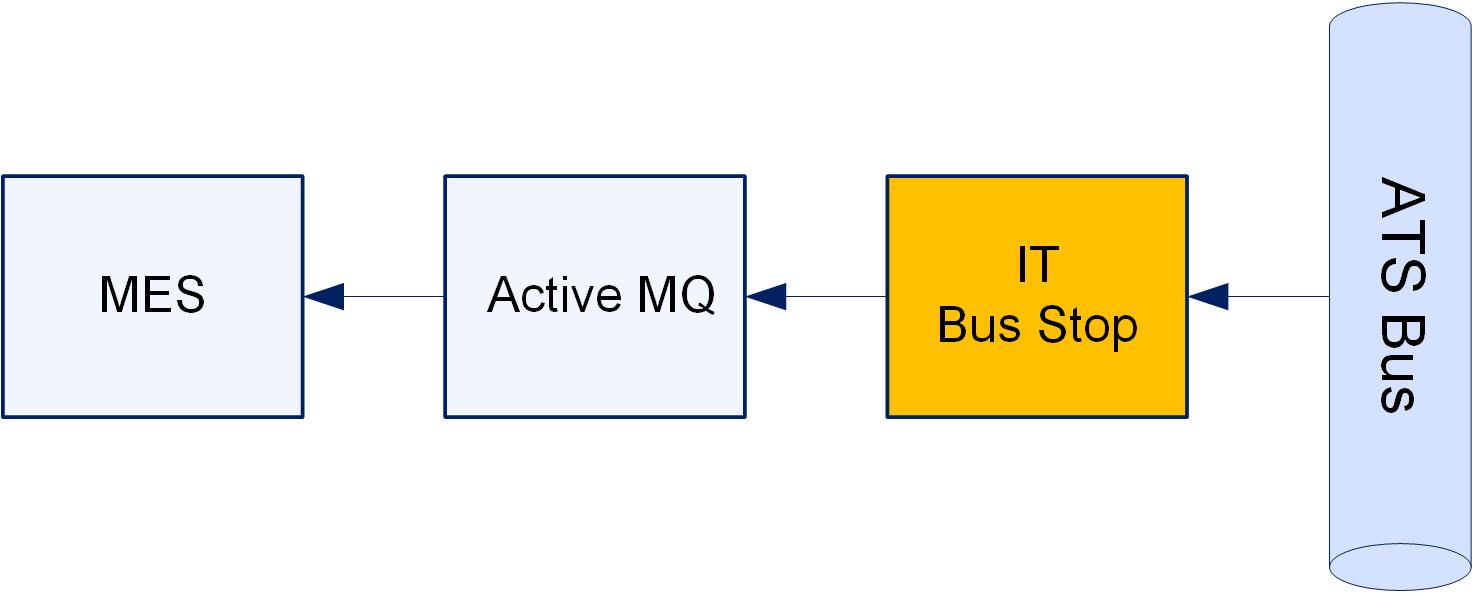

The request to start the order doesn't pass directly from the IT system to the IT Bus Stop. Instead, it passes through an industry standard message control system such as Active MQ.

The IT Bus Stop reads the order information coming from Active MQ and translates it into a message in the standard B2MML format used by ATS Bus.

The IT Bus Stop then publishes the message onto ATS Bus. Once a message has been published on the bus it can be read by anyone that subscribes to it.

For further information on publishing and subscribing see here.

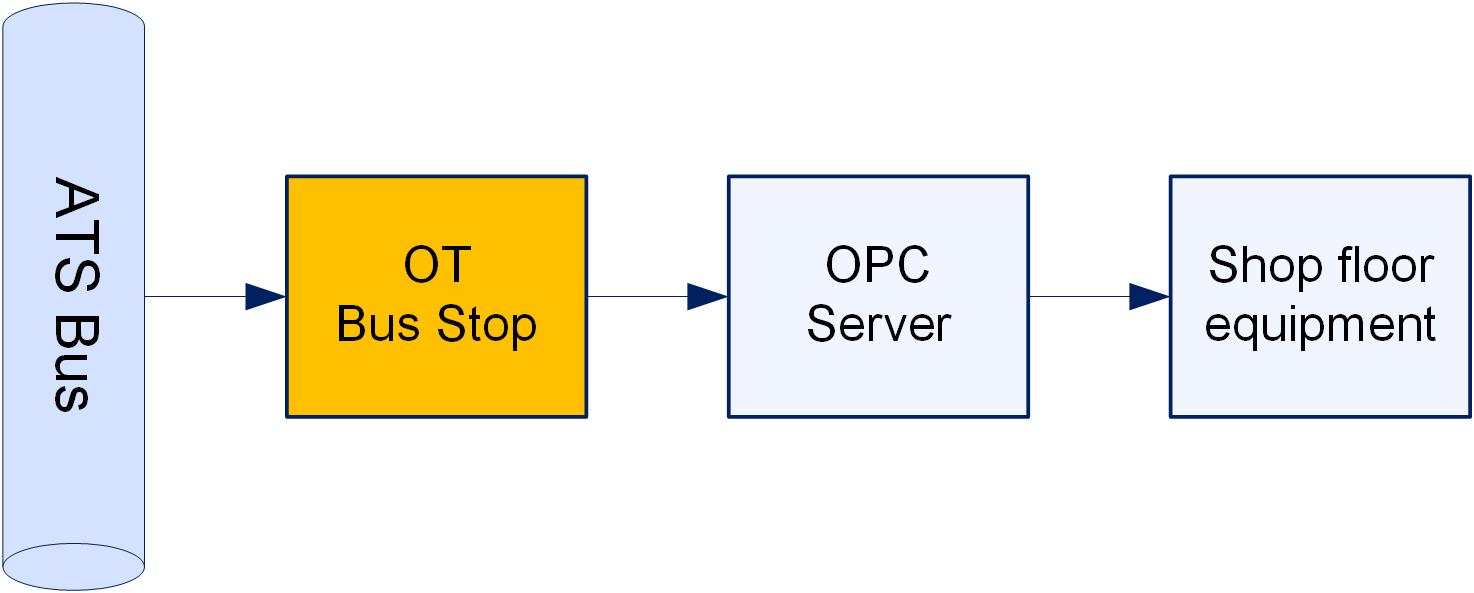

One of the Bus Stops that's subscribing to the message is an OT Bus Stop. It reads the information in the message and sees that a piece of equipment it's associated to needs to start an order.

Again, the Bus Stop isn't connected directly to the shop floor equipment. Instead it links to an OPC or XML server that handles data passing to and from one or more pieces of equipment.

The OT Bus Stop translates the order request received from the ATS Bus from the B2MML format into a format that can be understood by the OPC server.

The OPC server then sends the data onto the shop floor equipment in a format such as Profibus.

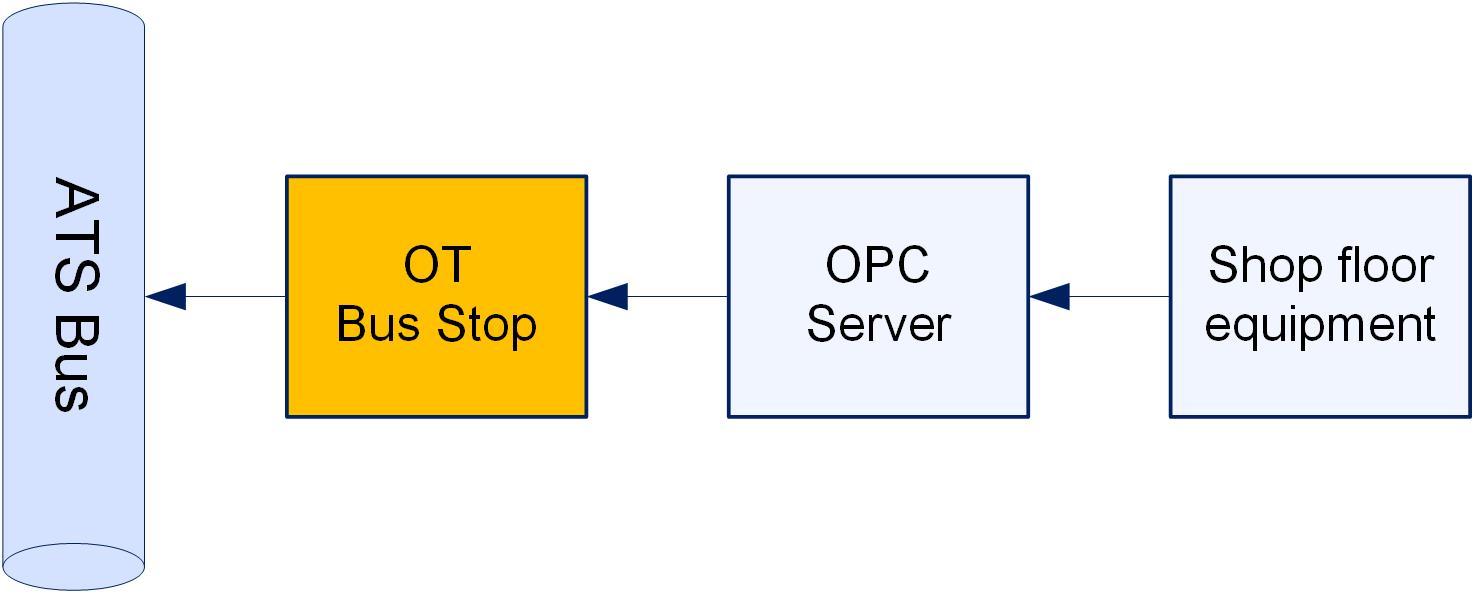

When the equipment has finished producing the order it sends messages to the OT Bus Stop, via the OPC Server, stating that the order has finished and how much material has been produced.

The Bus Stop translates the information into B2MML messages and publishes it on the ATS Bus.

The IT Bus Stop is listening for messages that contain production values and order status. It takes the information it needs from the messages on ATS Bus, translates it and sends it to Active MQ which sends it onto the IT system.

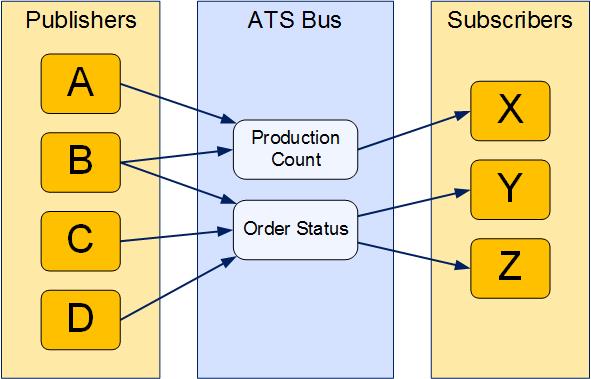

ATS Bus uses a publish-subscribe method to transfer data between senders and receivers. This means that the message senders, called publishers, don't specify where the message is being sent. Instead, each message is allocated to a particular type (e.g. production count, order status, machine status).

Subscribers express interest in one or more message types and only receive messages that are of interest. Using this method means that neither publishers nor subscribers need to know who is sending or receiving the messages. They simply send and receive their data via the Bus Stops.

This makes it a lot easier to add further equipment to the system which in turn means that the system is a lot more flexible.

ATS Bus has several features that make it our customers first choice.

For starters it can work in secure environments as it can use secure endpoints (https). This is a huge benefit to the defence and aerospace industry.

It has the ability to convert tag data to meta data. This means that when it receives a single value from the production line (e.g. a temperature) it can associate it with other known values (such as the time, the equipment name and the production batch) before sending it onto the bus. This contextual data makes it more usable by everything else attached to ATS Bus.

Another benefit is that it can take realtime data, such as a production order from the IT system, and turn it into event driven data. This could be done in a number of ways. For a production order it could place it in a queue and the production request won't be sent to the equipment until the previous production run has finished.

A major fear of any manufacturer is loss of data during production. This could be an order only being sent to some of the equipment or produced quantities not being sent back to the IT system. To prevent this ATS Bus buffers data locally and utilises hand shakes to ensure that data is received correctly. This avoids data loss and overcomes any issues of network latency.