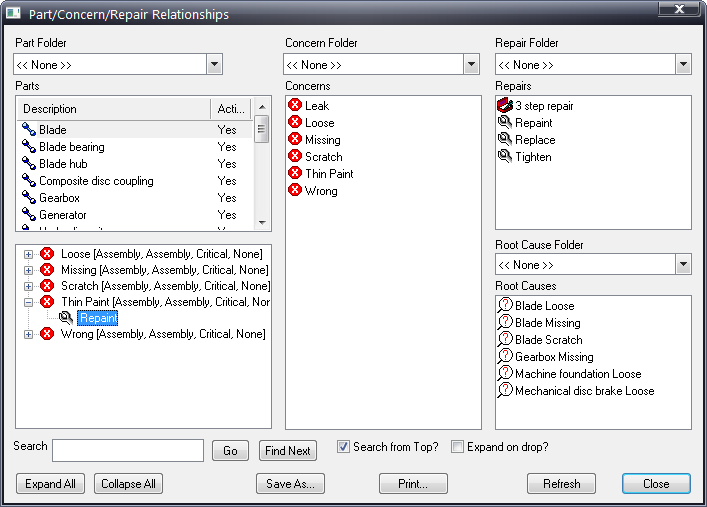

Setting up a Part/Concern/Repair (PCR) relationship defines the concerns and repair types available at the inspection and repair stations.

If you have multiple parts with the same concerns and repairs, you can add concerns to a part and then drag and drop that part onto another part. The concerns will be copied to the other part.

1. Click Defects > Part/Concern > Repairs.

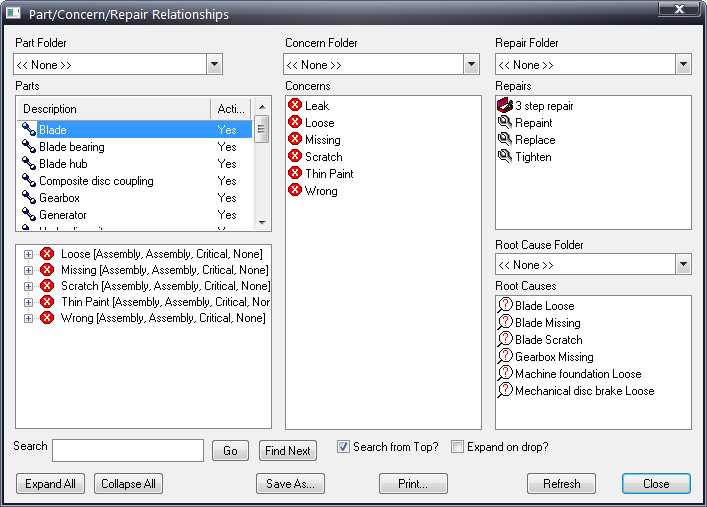

2. Use the Part Folder field to select a part folder. Select <<None>> to view all Parts.

3. Select a part in the Parts list. This is the part for which you are going to create a concern/repair relationship.

4. Use the Concern Folder field to select a concern folder.

Root causes are attached to the part/concern and are an attribute of the Defect in Data Collect.

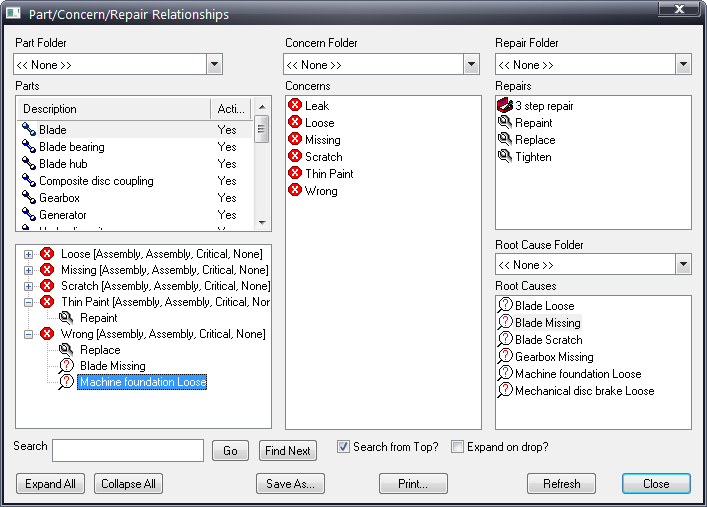

5. Select and drag a concern from the Concerns list onto the part's concern area. After the concern is dropped, the Part/Concern Properties dialog box opens. You can also right-click an existing concern to make changes.

You can add multiple concerns at the same time by clicking and holding Ctrl, selecting the required concerns and dragging them into the part's concern area.

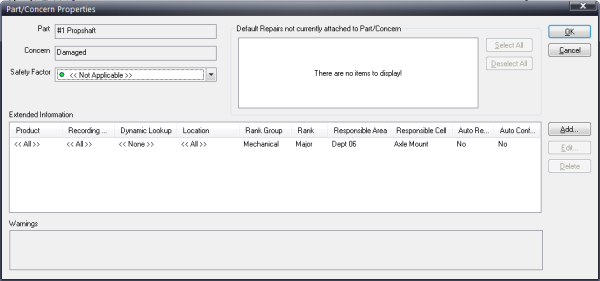

6. Use the Safety Factor field to define a safety level for this part + concern, if applicable.

7. Use the Default Repairs checkboxes to specify which repairs will be added by default to this part + concern.

The Extended Information grid at the bottom of the Part/Concern Properties dialog allows you to do the following:

Assign multiple responsible areas/cells

Assign multiple rank groups/default ranks

Auto-repair and auto-confirm defects

Each row in the Extended Information grid represents a different criteria and the settings within that row will only be applied to Part/Concerns that match that criteria. The first line is always the "default" and cannot be removed. The Product and Recording Area are always set to "All."

Add another responsible area/cell or rank group/rank assignments for different recording areas/products as needed. Whether the Responsible Area/Cells are selected automatically is determined by the station's Property Auto-select Resp Area/Cell on Defect setting.

Additional lines represent different recording area/product configurations. Different responsible area/cells may be added for different product lines. Multiple rank group/default rank assignments are also possible.

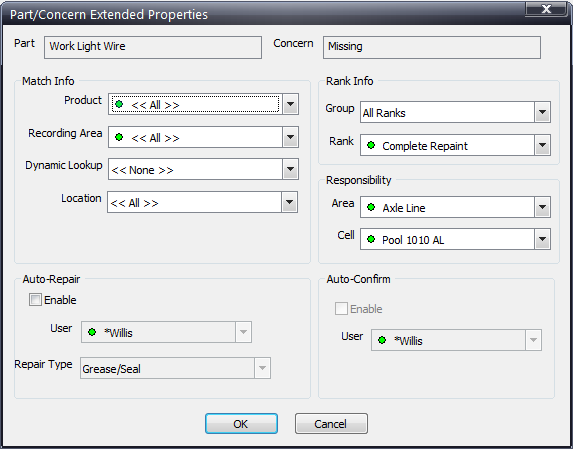

8. Click Add. This displays the Part/Concern Extended Properties dialog box.

If you have a duplicate Match Info, you will see a warning message in the warning message box. You will not be able to click OK (it will be grayed out) until you fix the problem. The problem can be fixed by changing or deleting the row.

9. Select the criteria in the Match Info drop-down lists. The Rank Info, Responsibility, Auto-Repair and Auto-Confirm settings selected will be applied to Part/concerns that match the criteria.

10. Select a Rank Group from the list. Only ranks in this group will be displayed for the specified part/concern.

11. Select a default Rank for this part + concern combination.

Setting the default will save the inspector time when entering in a defect – the inspector can either accept the default or choose another rank/severity.

12. Select a Responsible Area or department for this part + concern.

13. Select a Responsible Cell or zone for this part + concern.

14. To automatically repair defects as they are entered, check the Auto-Repair Enable checkbox and enter the associated User and Repair Type.

15. To automatically confirm defects as they are entered, check the Auto-Confirm Enable checkbox and enter the associated User.

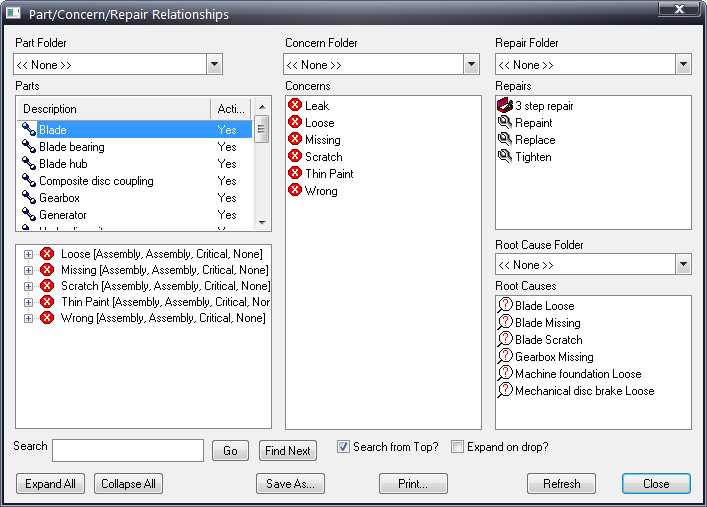

16. Click OK. You are returned to the main Part/Concern/Repair Relationships screen. Note that your concern has now been added to the display area with the specified repairs already associated with it.

17. In the part's concern area (where you dragged the concern), expand the concern.

Most repairs are configured using the Default Concern/Repairs dialog box, but they can also be modified here.

18. Modify repairs by using the Repairs list to drag repairs directly onto concerns as needed (or right-click an existing repair to modify it). Repairs may also be deleted from concerns by clicking a repair and pressing the Delete key.

19. If you have the Inspect Costing application enabled, you will see the Repair Properties dialog box that displays the supply cost and repair time. In the Supply Cost field, enter the cost of supplies used to make this repair for this part + concern.

See here for information on how to enable Costing.

20. In the Repair Minutes field, enter the estimated amount of manpower time to make this repair for this part + concern.

21. Click OK.

22. Repeat these steps as necessary to define other part/concern/repair relationships.

23. Root Causes may be dragged onto concerns as well.