The first step in setting up the Inspect system is to configure your plants. This involves identifying and assigning a code to each of the organizational elements within your manufacturing enterprise.

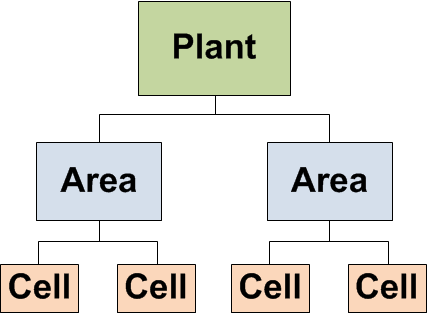

In Inspect, these elements are organized as shown in the following illustration.

The plant layout allows you to indicate where the checks are being carried out in the plant. Similarly, the operator will be able to state where a defect has occurred, or even which cell a unit needs to be sent to for re-work.