In Statistical Process Control, the Western Electric (WECO) Rules are decision rules for detecting "out-of-control" or non-random conditions on control charts. Locations of the observations relative to the control chart control limits (typically at ±3 standard deviations) and centerline indicate whether the process in question should be investigated for assignable causes.

The rules attempt to distinguish unnatural patterns from natural patterns based on several criteria:

The absence of points near the centerline (identified as a mixture pattern)

The absence of points near the control limits (identified as a stratification pattern)

The presence of points outside the control limits (identified as an instability pattern)

Other unnatural patterns (systematic (autocorrelative), repetition, trend patterns)

The most important of the Western Electric rules are the zone rules, designed to detect process instability and the presence of assignable causes. There are four basic rules that deal with appraising runs of observations within the various zones:

|

Rule |

Description |

Chart Example |

Problem Indicated |

|

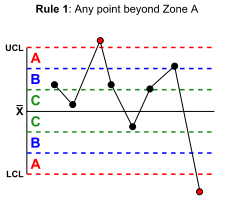

1 |

Any single data point falls outside the 3σ limit from the centerline (i.e., any point that falls outside Zone A, beyond either the upper or lower control limit) . |

|

One sample is grossly out of control. |

|

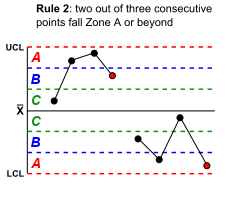

2 |

Two out of three consecutive points fall beyond the 2σ limit (in zone A or beyond), on the same side of the centerline. |

|

Some strong short-term bias exists. |

|

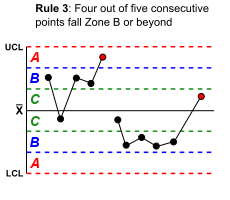

3 |

Four out of five consecutive points fall beyond the 1σ limit (in zone B or beyond), on the same side of the centerline. |

|

A weaker long-term bias exists. |

|

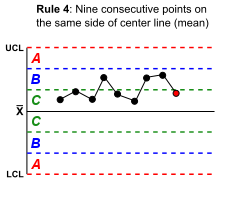

4 |

Nine consecutive points fall on the same side of the centerline (in zone C or beyond). |

|

Some prolonged bias exists. |