In this Topic Hide

First we must define what a defect is. A defect is a concern found on a unit. A defect contains information about the type of concern, its rank, root cause and many other details.

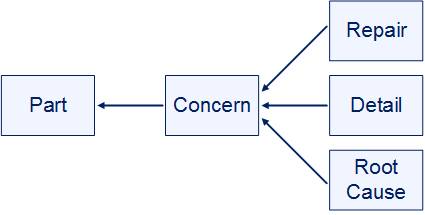

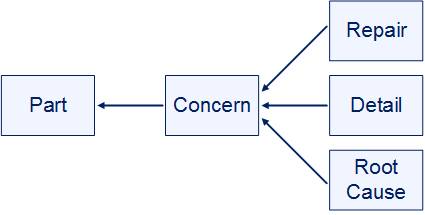

The main items you need to configure are parts, concerns, repairs, details and root causes which are associated together as follows:

This section provides a variety of information relating to configuring defects:

● Associate concerns with parts

● Associate repairs with parts/concerns

● Associate details with parts/concerns

● Associate root causes with parts/concerns

Setting default items will save the inspector time when entering a defect. The inspector can either accept the default or choose another.

● Specify rank group and default rank

● Specify default responsible area and cell

● Specify default repair types for configuration

● Specify default details for configuration

● Specify default responsible area and cell for configuration

● Specify Default Rank for configuration

● Copy Items Between Part in configuration