In this Topic Hide

Before configuring the system for automated data collection the manual configuration must be completed. For further information see here.

ATS Intelligence can record production and downtime information directly from the production line. In order for this to be achieved the system must be configured so that it knows where to collect the information from and how to translate it.

Once the system has been configured it can gather data automatically with little or no human interference required.

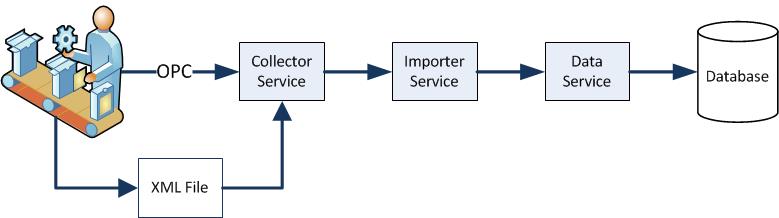

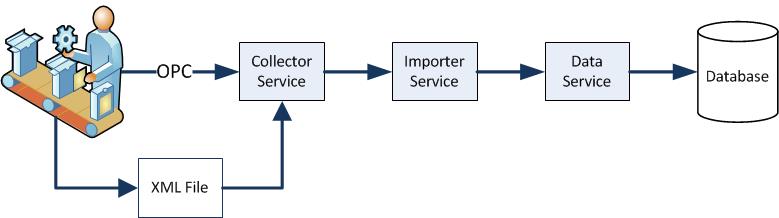

Information from the production line passes through three services in order to reach the database:

1. The Collector Service receives updates directly from the production line machines via one or both of the following methods:

§ OPC: The Collector Service reads information directly from OPC channels.

§ XML: Data is sent from the control layer to an XML file. The Collector Service then reads the information from the XML file.

2. The Collector Service pushes the information to the Importer Service which may be on another server. There may be multiple Importer Services which allows for scalability.

3. The Importer Service sends the information to the Data Service which updates the database.

Before configuring the system for automated data collection the general configuration must be completed. This involves configuring the materials, equipment and shift schedules. For further information see here.

| No. | Step | Description |

|

Create connection to production line |

||

|

1 |

Configure Importer Services |

The locations of the Importer Services are specified so that they can be found by the Collector Services. See here. |

|

2 |

Configure Collector Services |

The locations of the Collector Services are specified and associated to the Importer Services to which they will push their information. See here. |

|

3 |

Configure XML and OPC Channels |

The XML and OPC channels form the links between the production machinery and the Collector Services. They specify exactly where the information is and how it should be read by the Collector Service. See here. |

|

Configure machine mode/state identification |

||

|

4 |

Configure Machine Modes and States |

Machine Modes and Machine States specify what a machine is doing. They are declared by the machine using specific tags that can be read by ATS Intelligence. See here. |

|

5 |

Map Modes and States to incoming values |

The values that will be received from the machine are matched to Modes and States. See here. |

|

6 |

Assign Modes and States to downtime reasons |

The Mode/State combinations are associated to specified downtime reasons so that the OEE can be calculated. See here. |

|

7 |

Assign Modes and States of Equipment to Tags |

Each piece of equipment sending data automatically needs to have a tag (created within an OPC or XML channel) associated to its mode and state. See here. |

|

Configure material type and quantity identification |

||

|

8 |

Map Materials to received values |

Production materials can be specified by the production line by mapping materials to tag values. |

|

9 |

Assign Material tags to equipment |

Each piece of equipment can have its production run material specified in different ways. It could either be specified in Data Collect during runtime, it could copy another equipment or it could be received from the production line. See here. |

|

10 |

Configure Counters |

Counters are used to calculate the total number of good and bad items produced by using information from specified tags. Counters are configured in the Equipment Hierarchy. See here. |

|

Configure process variables |

||

|

11 |

Configure Process Variables |

Process Variables are used to collect extra information that isn't required to calculate the OEE but that could be useful in analyzing it. This could include things such as temperatures, pressures and cycle times. Process Variables can't be viewed in Data Collect but can be viewed in Reporting. See here. |

The only configuration that may be required during runtime is to assign specific materials to production runs. ATS Intelligence only records the amount of material that has been produced and not what the specific material was. It uses the default material and design speed for the machinery to carry out OEE calculations.

The material can be specified by modifying the production run in Data Collect during runtime. For further information see here.